Intro

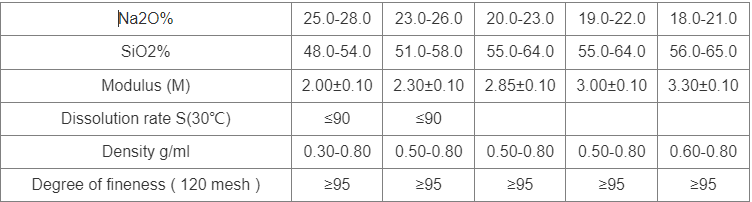

(Technical Parameters of Powdered Instant Sodium Silicate (CAS 1344-09-8))

With the growing global focus on environmental protection and sustainable growth, salt silicate, likewise referred to as water glass or hydrated salt metasilicate, is obtaining raising focus in different commercial markets because of its wide range of applications. Sodium silicate plays a crucial duty not just in sectors such as building and papermaking but likewise in detergent manufacturing. In recent years, conventional phosphate-based detergent ingredients like salt tripolyphosphate (STPP) have been terminated because of their serious impact on water top quality. For that reason, there is an urgent requirement to locate reliable and environmentally friendly options. In this context, sodium silicate has gained significant interest because of its one-of-a-kind performance benefits.

Introduction of Sodium Silicate

Salt silicate is a substance created from silicon dioxide (SiO ₂) and sodium oxide (Na ₂ O), with a chemical formula generally stood for as Na ₂ O · nSiO ₂. Relying on the worth of n, it can be identified right into different types. Sodium silicate displays exceptional solubility, high pH, and outstanding cleansing power, making it a suitable cleaning agent additive. Past its use in cleaning agents, sodium silicate is extensively used in the construction market as a waterproofing product and sealer; in the paper market, it enhances paper stamina and level of smoothness; and it likewise plays crucial duties in fabric dyeing, oil removal, and other areas.

Production Refine of Salt Silicate

The manufacturing procedure of sodium silicate includes numerous essential steps:

1. Raw Material Prep work: Making use of moisturized sodium metasilicate (or quartz sand) and caustic soda as base products.

2. Dissolution Phase: Blending the raw materials and heating them to an ideal temperature to advertise dissolution, making sure all elements are totally integrated.

3. Formation Treatment: Managing problems to form specific crystal structures, which requires specific guideline of temperature and stress.

4. Filtration and Splitting Up: Utilizing a plate and frame filter press to get rid of excess water and impurities, ensuring product purity.

5. Drying out and Forming: Utilizing spray drying out innovation to additionally reduce the moisture content of the product, inevitably creating a powdered final product that is simple to shop and transport.

Cost-Benefit Analysis

From an economic point of view, the production of salt silicate supplies substantial cost advantages. For a manufacturing range of 5,000 bunches each year, the cost evaluation is as complies with:

1. Variable Prices: Around $346.71 per ton, mostly consisting of resources (hydrated sodium metasilicate/quartz sand + caustic soda), power consumption (electricity + gas), and labor prices.

2. Fixed Costs: Regarding $141,400 every year, covering devaluation and maintenance of fixed possessions, administration costs, lending passion, and various other expenses.

3. Complete Cost: After extensive consideration, the estimated expense per lots of finished item is around $385.71.

4. Sales Earnings: With an approximated selling price of 642.86 perton, aprofitmarginofabout642.86 perton, aprofitmarginofabout257.15 per lot can be attained.

5. Economic Benefits: The yearly output worth can get to 3,214,300, contributingapproximately3,214,300, contributingapproximately1,285,700 in tax obligation profits.

This cost-benefit evaluation suggests that sodium silicate not just has significant technological benefits but likewise high economic expediency. For makers, investing in the manufacturing and promo of sodium silicate can yield significant financial returns while boosting the company’s social responsibility image.

Market Lead

1. Global Market Demand

Worldwide production of synthetic detergents is continually expanding, particularly with the raising proportion of ultra-concentrated powders. It is approximated that at least 230,000 lots of salt silicate were needed in 2000 alone to meet market demand. Currently, international sodium silicate manufacturing is limited, resulting in a significant supply-demand void, showing considerable growth potential. As international customers’ demand for top notch living rises, the demand for environmentally friendly cleaning agents will also grow, thereby broadening the market for salt silicate.

2. International Competitiveness

Compared to a lot of international competitors, Chinese-produced salt silicate not only supplies a clear cost benefit but also keeps top quality, making it extremely affordable in export markets. As an example, the FOB price of salt silicate products in the United States is about $51.15 per 100 extra pounds, while European rates are also greater. This indicates that Chinese-produced salt silicate has solid competitiveness in the international market. Via constant technical development and quality enhancement, Chinese-produced salt silicate is positioned to catch a larger share of the international market.

( sodium silicate)

Conclusion

In recap, salt silicate, with its superior technological performance and reduced production prices, shows great potential in replacing typical phosphate-based ingredients. Despite significantly stringent ecological laws and consumers’ quest of top notch living, increasing the study and industrialization of sodium silicate will undoubtedly become a key consider driving the updating of the worldwide detergent sector. For investors, entering this field not just assists improve the business’s social obligation photo yet likewise brings substantial economic returns and social advantages. With technological innovations and broadening markets, the application potential customers of salt silicate are really broad, making it a valuable location for expedition and development by appropriate business and study organizations.

High-quality Salt Silicate distributor

TRUNNANO is a supplier of Sodium Silicate Materials with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about sodium silicate co2, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us